Project

Electronics Devices Division

default

Business Outline

Electronic Devices Division realize the expansion of Magnet wire business through a secondary processing of Magnet wire, and extend our business field from material industry to more advanced and high added value industries besides. This division aims at the integrated production process from the technological development to mass production to meet customer’s advanced needs.

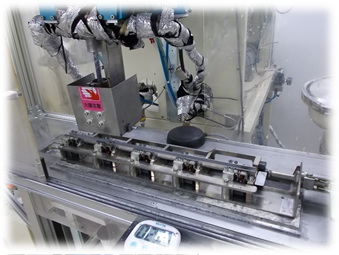

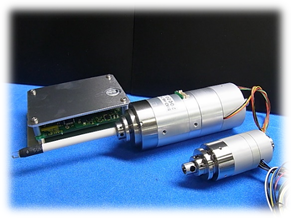

◆ Motor Section (Various Kinds of Motors)

We produce the motors related to factory and office automation consigned by the major motor manufactures. As for the cooling AC fan motor, we produce the stator & rotor processing, winding, blade assembly and motor assembly. We also cope with various needs to develop and produce the motors for FA, medical equipment and so on.

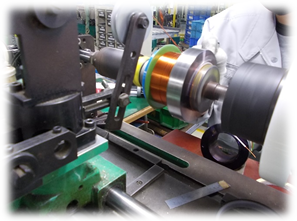

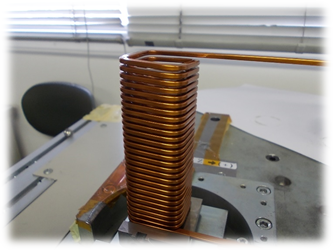

◆Coil Processing Section (Edgewise Coils)

We developed the winding method entitled the rolling method for rectangular wire, and realized the mass production of super high heat resistant coils putting ceramic insulation layer to practical use that is the unique production method. (Patented in Japan & USA.)

We have 2 kinds of edgewise winding method in the field of coils using rectangular wire, that is, the rolling method is for circular coil, another new method that we obtained the patents and the other company can’t produce is for square shape coil. The new winding methods make it possible to produce high heat resistance coils with ceramic insulation layer and low inflate shape coils.

◆ Car Component Section

We produce electric and electronic devices for automobile such as starting relay and alternator for diesel engines as OEM production. Also, we produce solenoid coils for motor bikes using our own developing Magnet wires, and coils for DC/DC convertors being effective in fuel improvement for gasoline engine vehicle besides. It is needless to say that these products have high reputation from customers.